Plastic injection moulding might be the most favored production strategies for creating plastic elements and parts at scale. Recognized for its precision, performance, and versatility, injection moulding is used throughout numerous industries—from automotive and electronics to customer goods and healthcare devices.

Exactly what is Plastic Injection Moulding?

Plastic injection moulding will involve injecting molten plastic in a pre-designed metal mould less than higher pressure. The plastic cools and solidifies through the mould, working with design of a ultimate item. When the component is completely cooled, it really is ejected from your mould and also the cycle begins yet again. This method is extremely repeatable, which makes it well matched for mass output.

Important Strengths

One particular with the big advantages of plastic injection moulding is having the ability to make sophisticated styles with fantastic accuracy and consistency. It’s also highly Price tag-successful for high-quantity operates, because the very same mould can be employed to generate thousands—as well as tens of millions—of similar elements with minimal substance squander.

Also, a variety of plastics can be used alongside the best way, which includes engineering-quality polymers like ABS, Nylon, Polycarbonate, and Polypropylene. These products offer you various attributes which include overall flexibility, durability, chemical resistance, and thermal stability, depending on the software.

Programs Across Industries

Plastic injection moulding is employed in just about any market. In automotive producing, it helps build dashboards, clips, read more and housings. In Health care, it’s utilized to create healthcare-quality syringes, containers, and device casings. Electronics brands depend upon it for creating strong plastic enclosures, buttons, and connectors.

Tooling and Mould Style and design

The quality of the final products relies upon closely over the style with the mould. Toolmakers use CAD software program to style and design precision moulds, which may be made out of hardened metal or aluminium. When the Preliminary price of mould development could possibly be large, the long-expression production effectiveness will cause it to become a respectable financial investment for large-scale initiatives.

Sustainability and Recycling

Modern plastic injection moulding facilities can even be adopting more sustainable methods. Leftover plastic-style are frequently reground and reused. Organizations like Australian Consolidated Plastics even supply plastic recycling companies for elements like Acrylic and Polycarbonate, endorsing a round overall economy in production.

Conclusion

Plastic injection moulding continues to be a cornerstone of contemporary manufacturing. Its performance, versatility, and ability to deliver consistent high quality aid it turn out to be probably the most most popular option for firms needing reliable, substantial-volume plastic manufacturing. As products and technologies evolve, the technique will keep on to be a little more sustainable and sophisticated—meeting the pressure of industries all over the world.

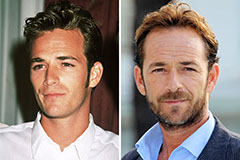

Luke Perry Then & Now!

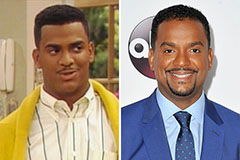

Luke Perry Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!